IN JUST A FEW CLICKS,

APPLY THE « 5S » RIGOROUS METHODOLOGY TO OBTAIN A BETTER EFFICIENCY OF PLCs

| 1. SORT | Delete the dead code, prohibited instructions, unused or inconsistent program elements to improve the quality of the PLCs. |

| 2. FILE AWAY | Organize the programs and data structure making sure that each program element is in the right place. |

| 3. CLEAN | Search, filter errors and programming defects based on more than a hundred criteria of control, adjustable and customizable in accordance with the needs of the projects and customers. |

| 4. STANDARDIZE | Check the conformity of the programs, the compliance of the programming standards, the comparison with a model program, the versions applied, the accuracy and consistency of the diagnosis of all components … |

| 5. RESPECT | Use this functionality during each phases of the project, from development to the qualification process, to the final acceptance of the PLC programs. Improve significantly the quality achievements and the readability of the programs. |

TECHNICAL SUPPORT TOOL DEDICATED TO CONTROL THE PLC PROGRAMS DAILY

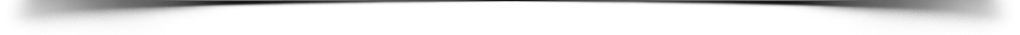

| CONFIGURE | Set the control items, associate a PLC model program and specification files such as the Inputs / Outputs list or diagnostic messages. In option, using an external configuration file « Process descriptor ». |

| CONTROL | Within moments, get the list of the errors found of all the PLC program, classified depending on the control items. |

| SELECT | Access the complete list of non-respected items and the precise location of corresponding errors and anomalies inside the PLC program. |

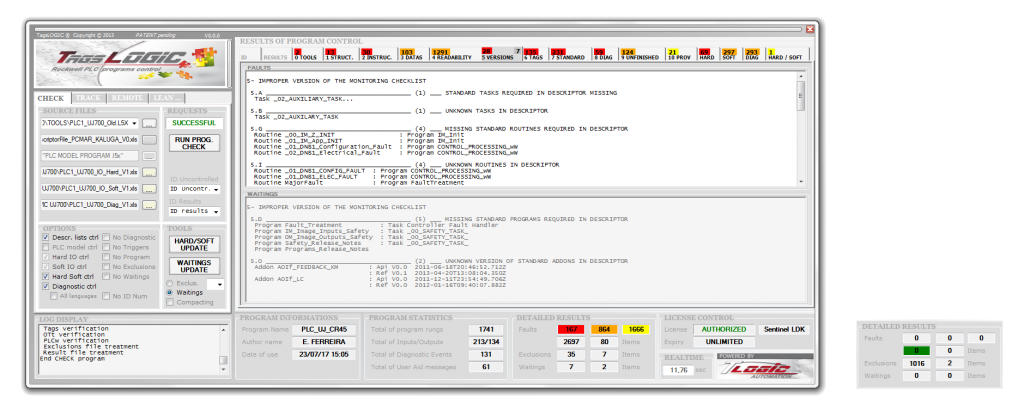

| QUALIFY | Validate and sign the automation programs before delivery to the customer. |

KEEP SAFE A GREAT PERFORMANCE AND QUALITY LEVEL OF PLC PROGRAMS

| RESOLVE | Check, correct or filter, one by one or in groups, all the errors and anomalies detected, until a perfect outcome of the PLC program is reached. |

| SUSTAIN | Maintain an optimum operational state of the PLC program on an ongoing basis. |